The "Lobster Pot" time lapse camera is at the heart of our service at Lobster Pictures. At first glance, it could be mistaken for a regular CCTV camera, but look a little closer and you'll see there's a lot more inside than meets the eye! Well over a decade of R&D has gone into our cameras and - where at all possible - we champion local businesses here in Bristol and the surrounding area, to provide us with its bespoke parts.

This week, take a look those companies whose technical expertise and long-standing experience in their field, provides us the honed, efficient camera systems we are able to provide our clients with.

CAMERA ENCLOSURE

The enclosure of our Lobster Pot was designed in-house and is formed of a simple and robust aluminium enclosure, which enables us to continually upgrade the internal components so our system stays up to date. We can also custom-build Lobster Pots to different specifications depending on the job required, including just recently, spraying two Lobster Pots black - in what we have affectionately named 'The Stealth Pots' - to blend in with their particular surroundings.

To-date, the same enclosure has contained everything from a Canon EOS 1000D to the latest Canon 5DS R and Nikon D810, plus a range of lenses with focal ranges from the wide angle 8mm, to the super telephoto Canon 70-200mm L series. We even take special requests from customers. Being able to use such a wide range of DSLR cameras and lenses in our system means we can capture the best quality image of our subject matter.

Additionally, we designed the bespoke 3-axis knuckle that the camera sits on, so the Lobster Pot can be freely panned, tilted and levelled. We can also design and build custom brackets to conform to different spaces, and have installed our time lapse cameras on listed buildings, hidden in flower beds and even attached them onto the jib of a crane on a A2Sea jack-up barge.

Our CAD models are fabricated by Dave Heinrich and his team at L.W. Jenkins Ltd, a local Bristol firm that started in 1976. We make any excuse to visit, have a chat and see their new Amada Laser cutter in action. This machine is a huge 3 by 1.5 meters - it's always great to peer through the little safety window and watch it in action, cutting out our components.

It’s really important for us to have a friendly local supplier - Dave has a wealth of experience in metal fabrication, and if needs be, we can easily pop round and collect. It also means we have control over everything from the grade of steel on the fittings to the type of paint they are sprayed in.

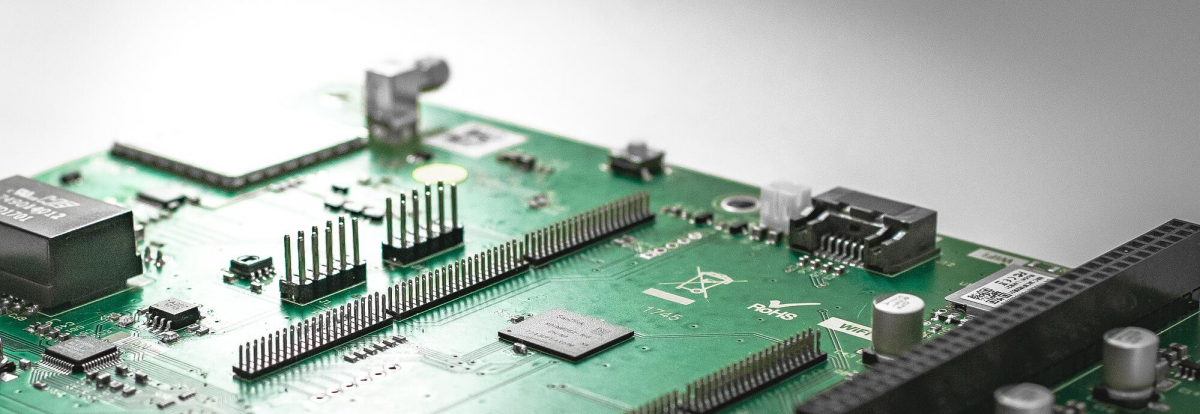

COMPUTER - THE CRAB

Inside the Lobster Pot is a small, energy efficient computer and a telemetry system. These two units consist of printed circuit boards that were imagined and designed in-house, and developed in collaboration with Cubik Innovation, another Bristol based business. This enabled us to easily meet face-to-face, exchange ideas and quickly re-iterate PCB designs.

We also have some talented programmers in Lobster Pictures writing the code that runs on these devices, giving us control over every last detail, and continually developing and introducing new features.

MADE IN BRISTOL

There's so many smaller - but still crucial - components which make up our Lobster Pots, all the way down to the steel tie-backs which secure our Pots at height, which we purchase from Bristol Rope and Twine. All these elements come together at our workshop at 26 Queen Square, Bristol and are assembled and tested by our workshop manager Andy Rodgers, who previously worked developing and building underwater autonomous vehicles. This bespoke engineering and attention to detail ensures Lobster are able to continue providing the highest spec of time lapse cameras to our customers, to capture those landmark projects - year after year.

Would you like to know more?

Drop us a message today to find out more - we'd love to hear from you.